Bespoke software to use alongside our products. Developed by FABRX·AI

Software Solutions for Every Need

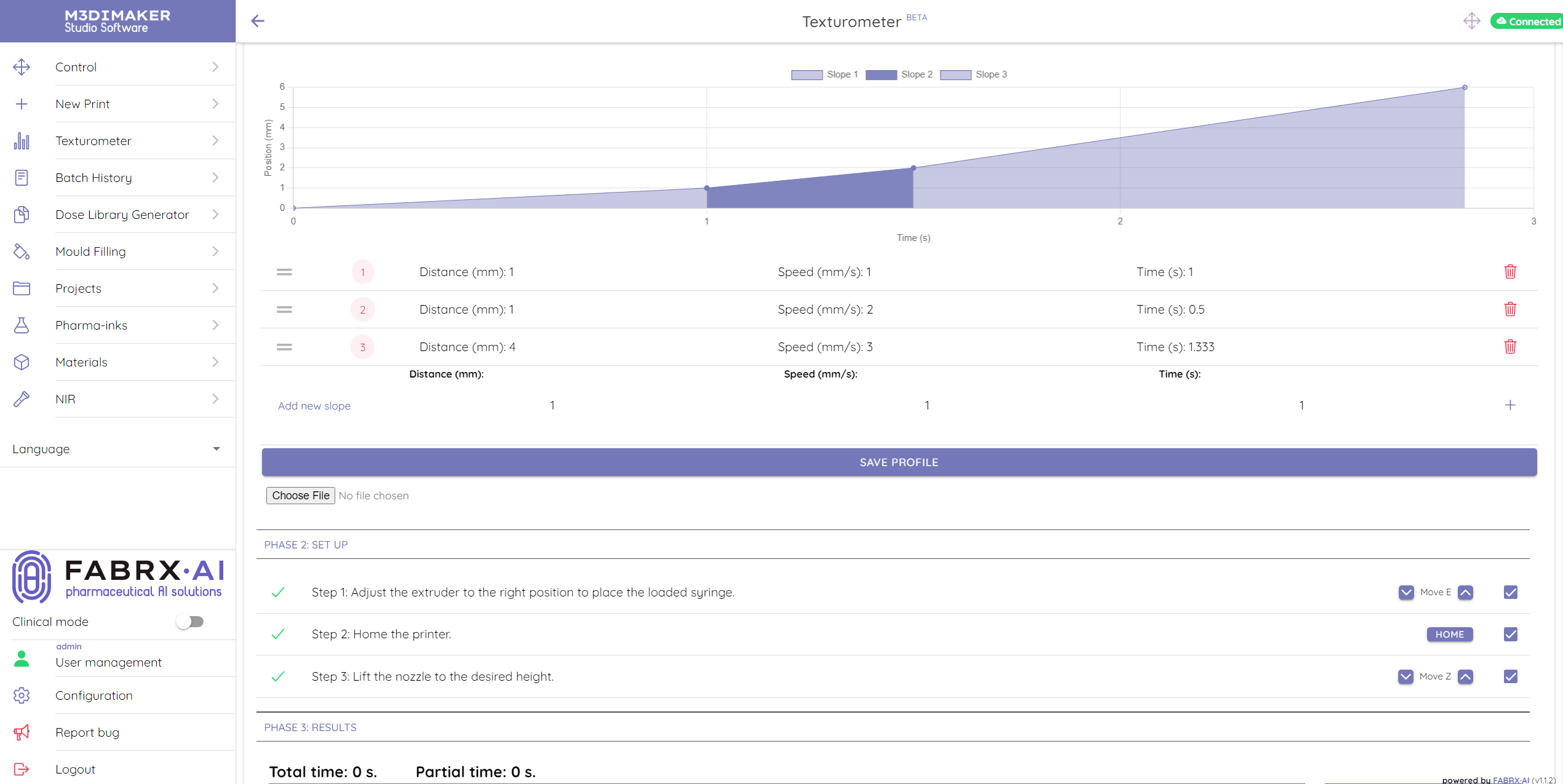

M3DIMAKER Studio is our easy-to-use, advanced software that facilitates efficient, fully customisable and precise 3D printing. It can be used to select your 3D model, prepare 3D printing parameters, and control the M3DIMAKER printers. For R&D, this software is non-restrictive, allowing you to print to your project’s specifications freely. For clinic use, protocols can be locked to ensure quality assurance. It can also be used alongside our in-built camera and quality control upgrades for real time analysis.

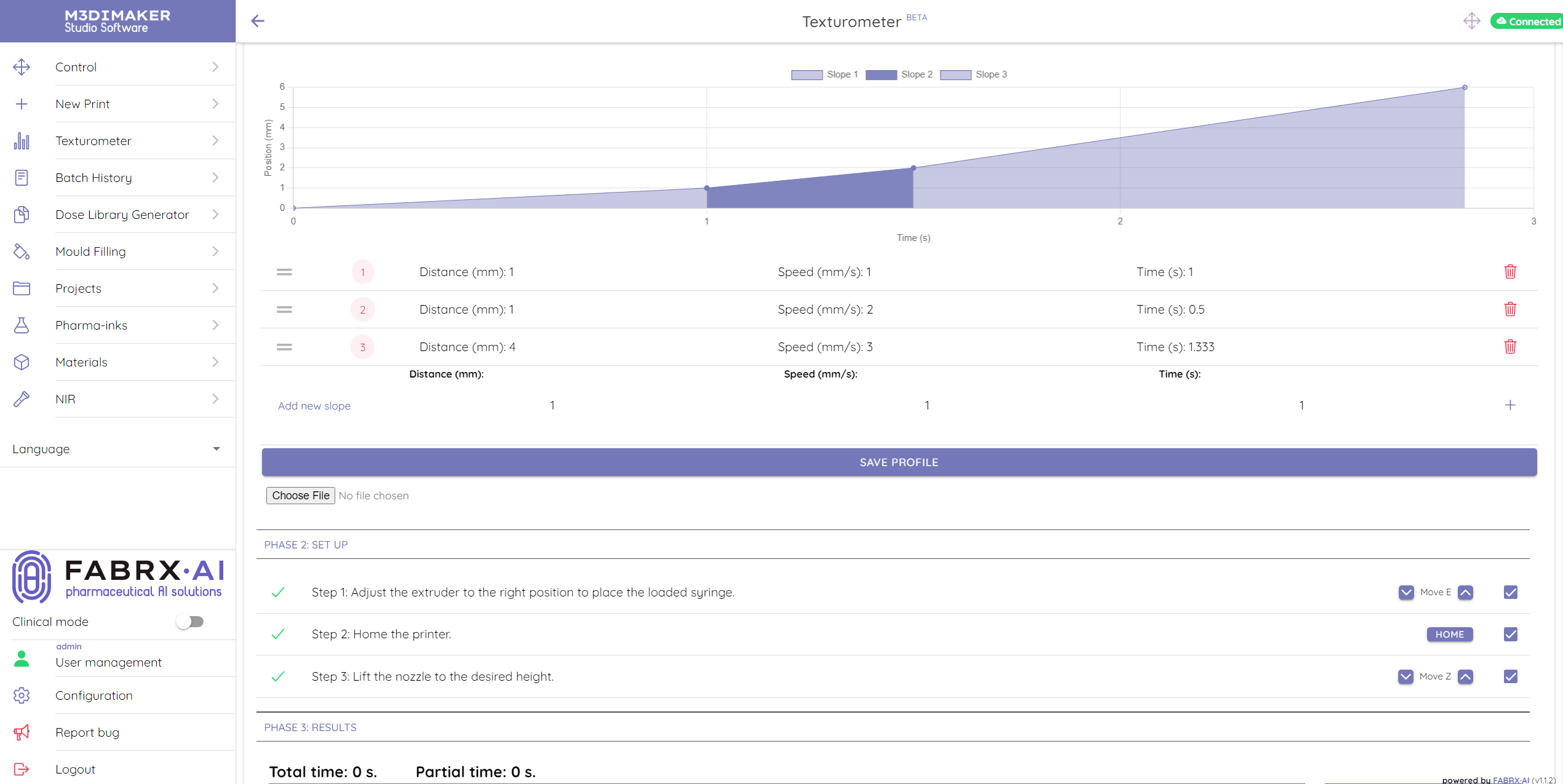

Control our in-built quality control technology using M3DIMAKER Studio. Track pressure and bubble formation using our SSE Laguna printhead, weigh and scan each tablet with our in-built balance and near-infrared spectrometer respectively.

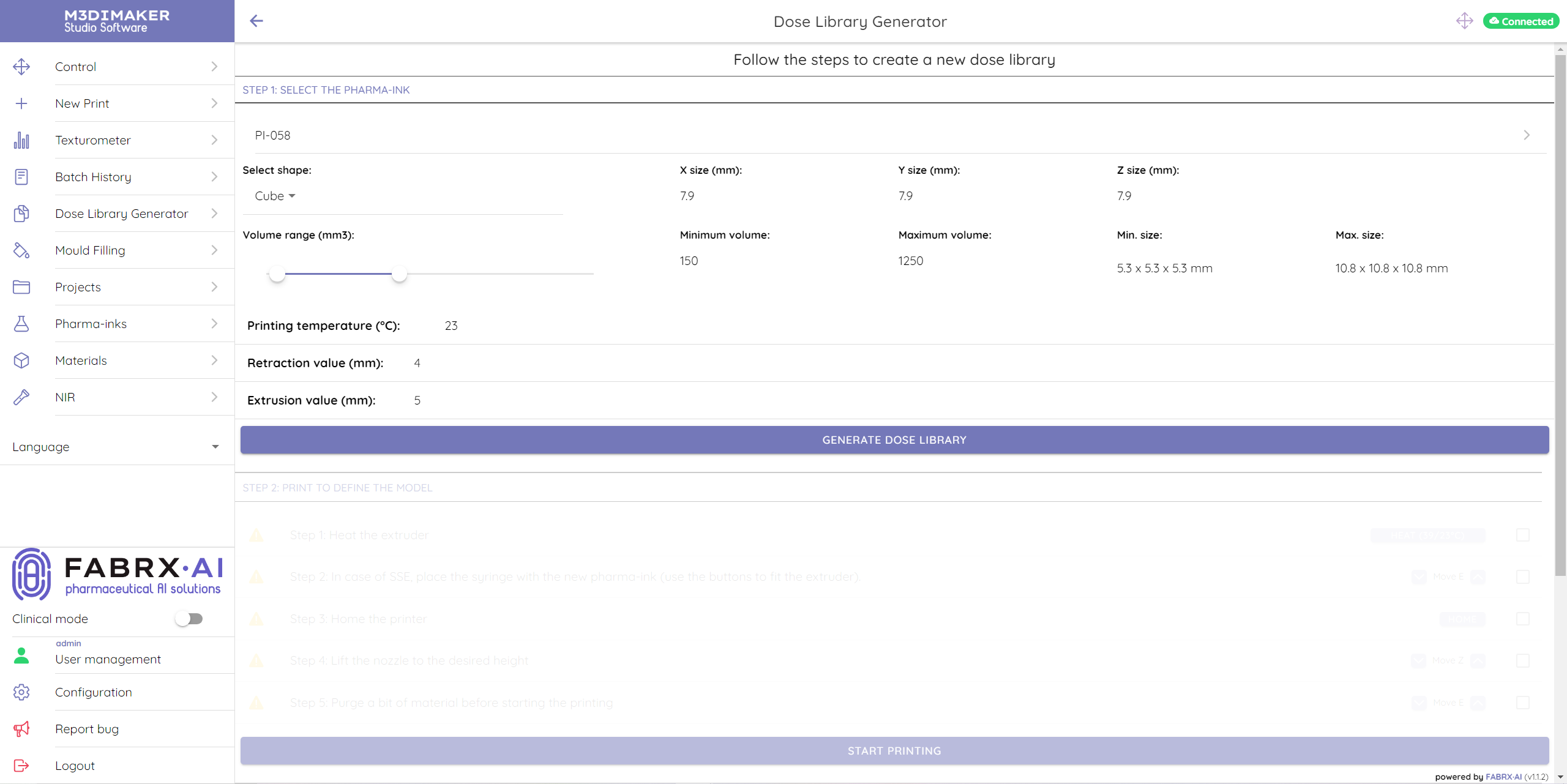

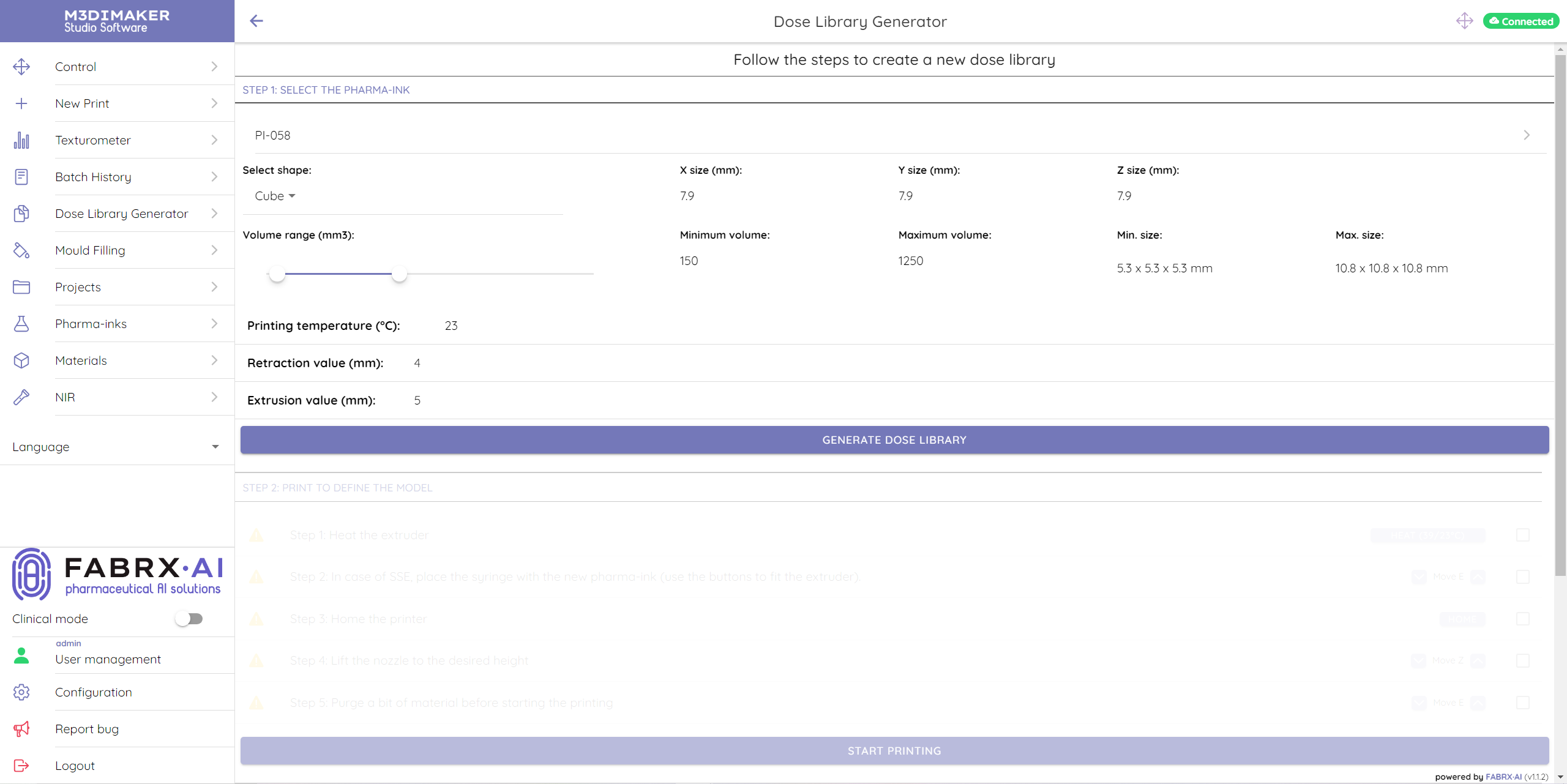

Make protocols easy to use in busy pharmacy settings with our dose-library generator, streamlining printing into just a few clicks.

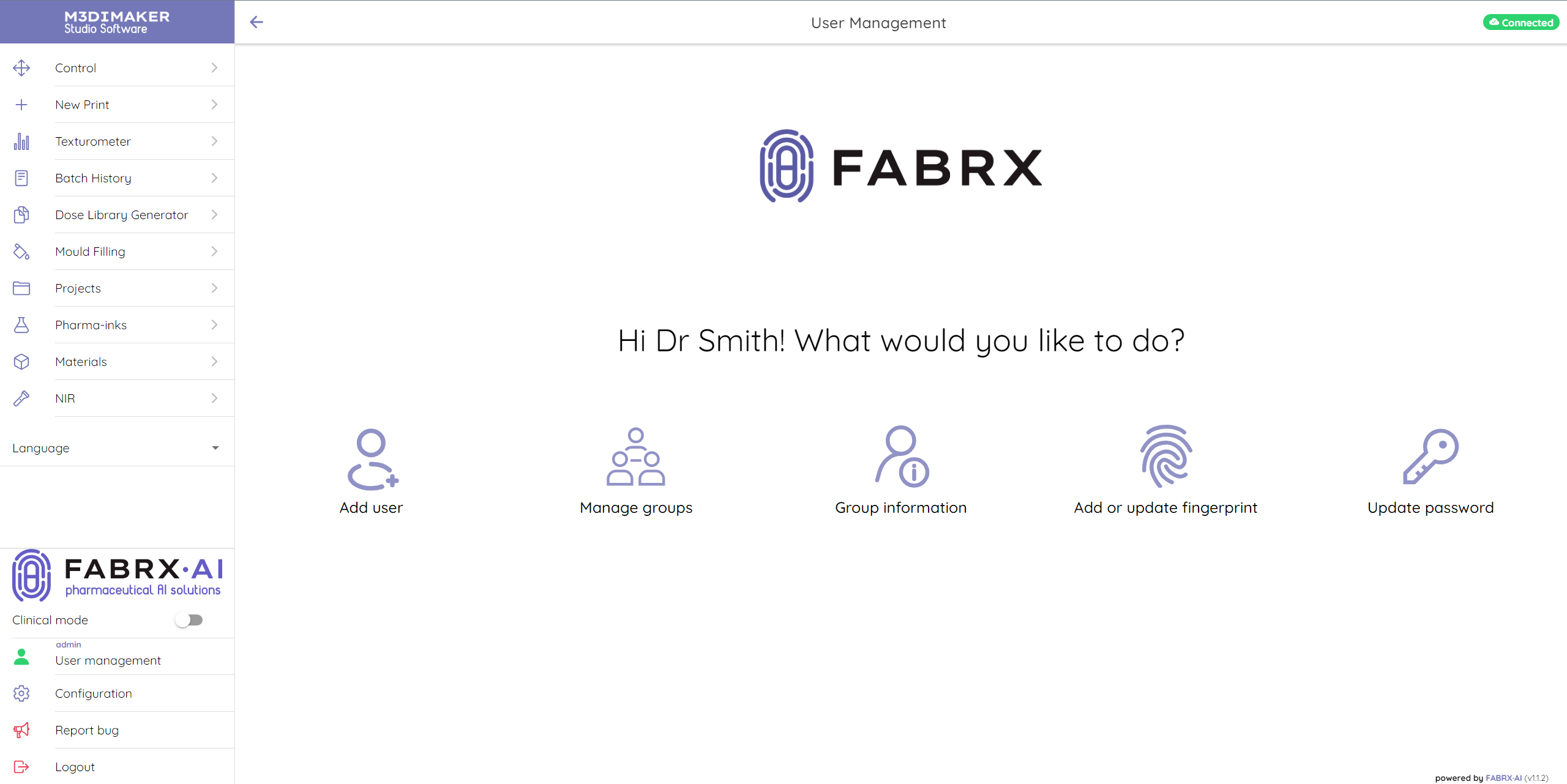

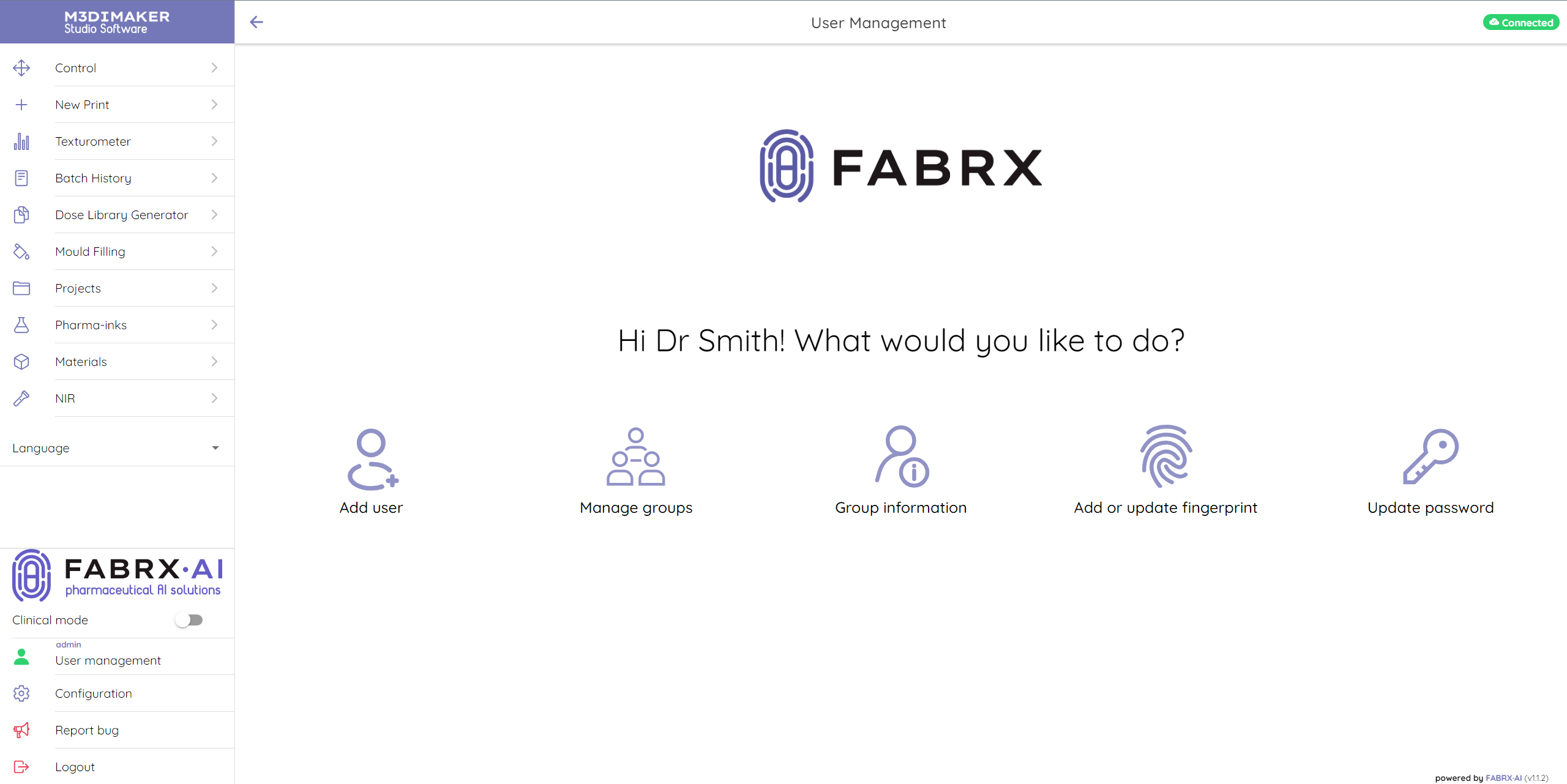

Create different groups to manage your users and printers. You can also assign different roles to each user.

Use M3DIMAKER Studio to fully control the M3DIMAKER pharmaceutical 3D printers, from choosing your 3D model to changing the 3D printing parameters. This can be freely used for research and development, or restricted for controlled use in healthcare.

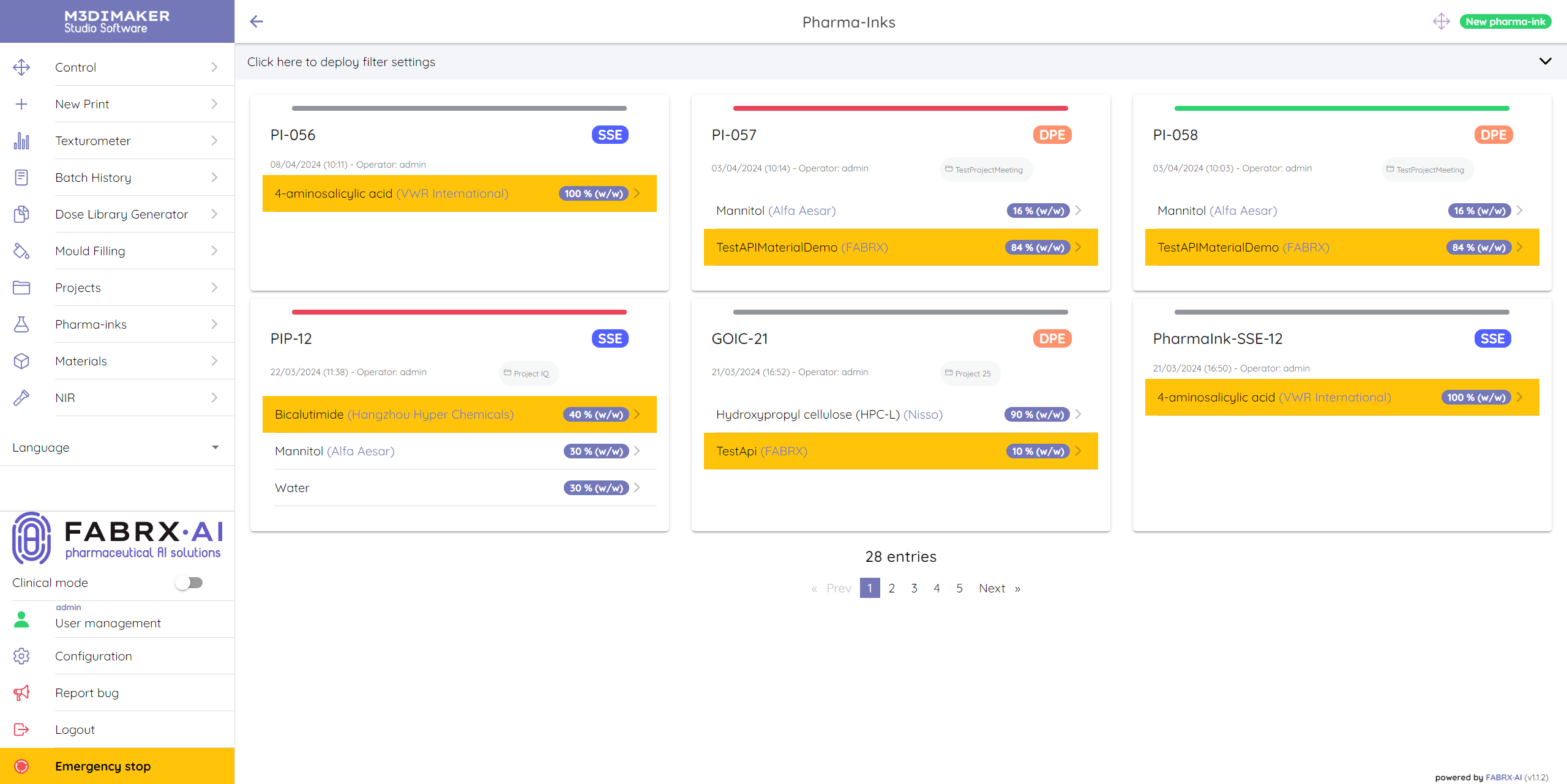

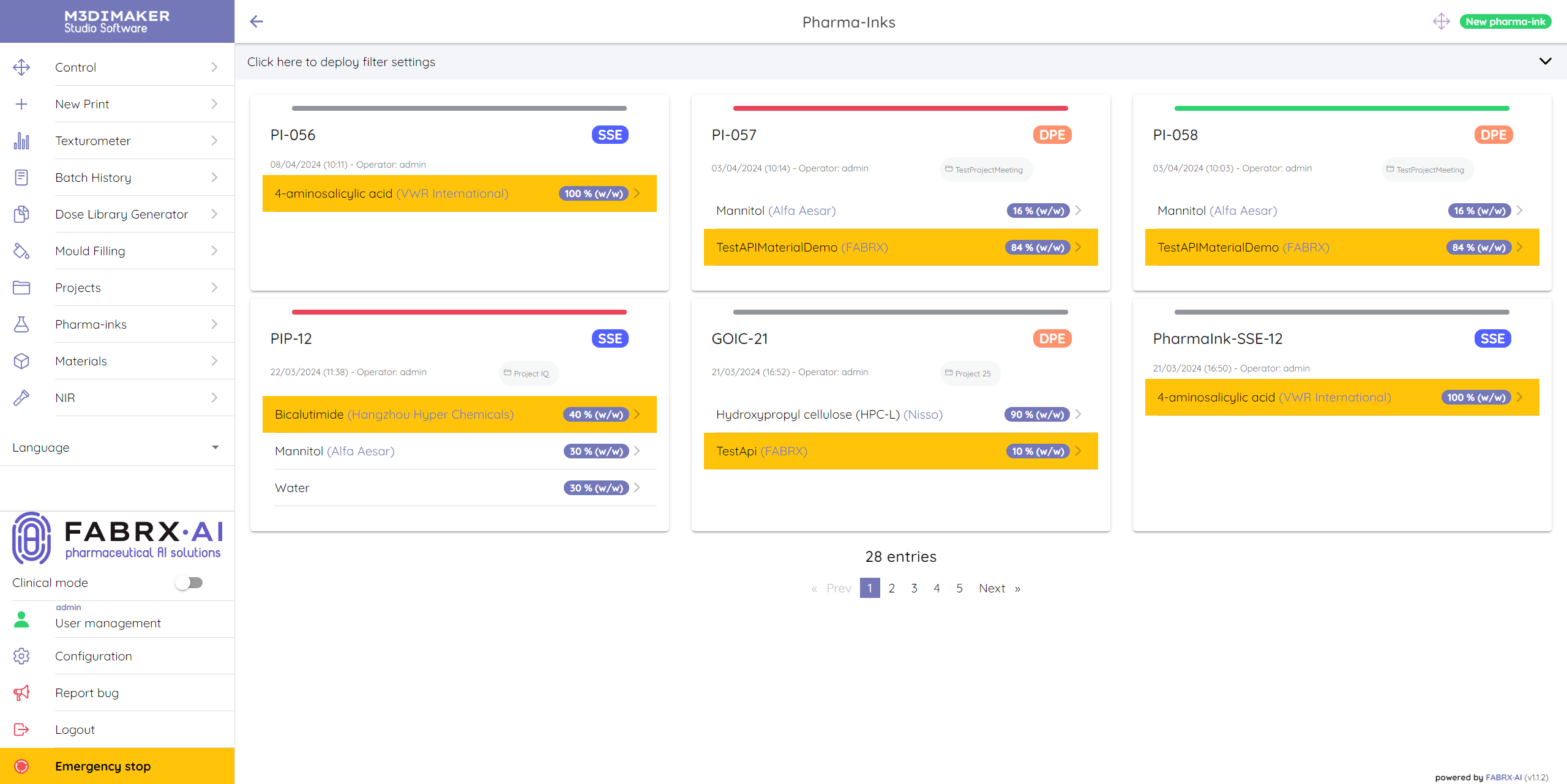

Create your own pharma-inks, using our database material or adding your own. Add the preparation protocol and test and track different parameters easily.

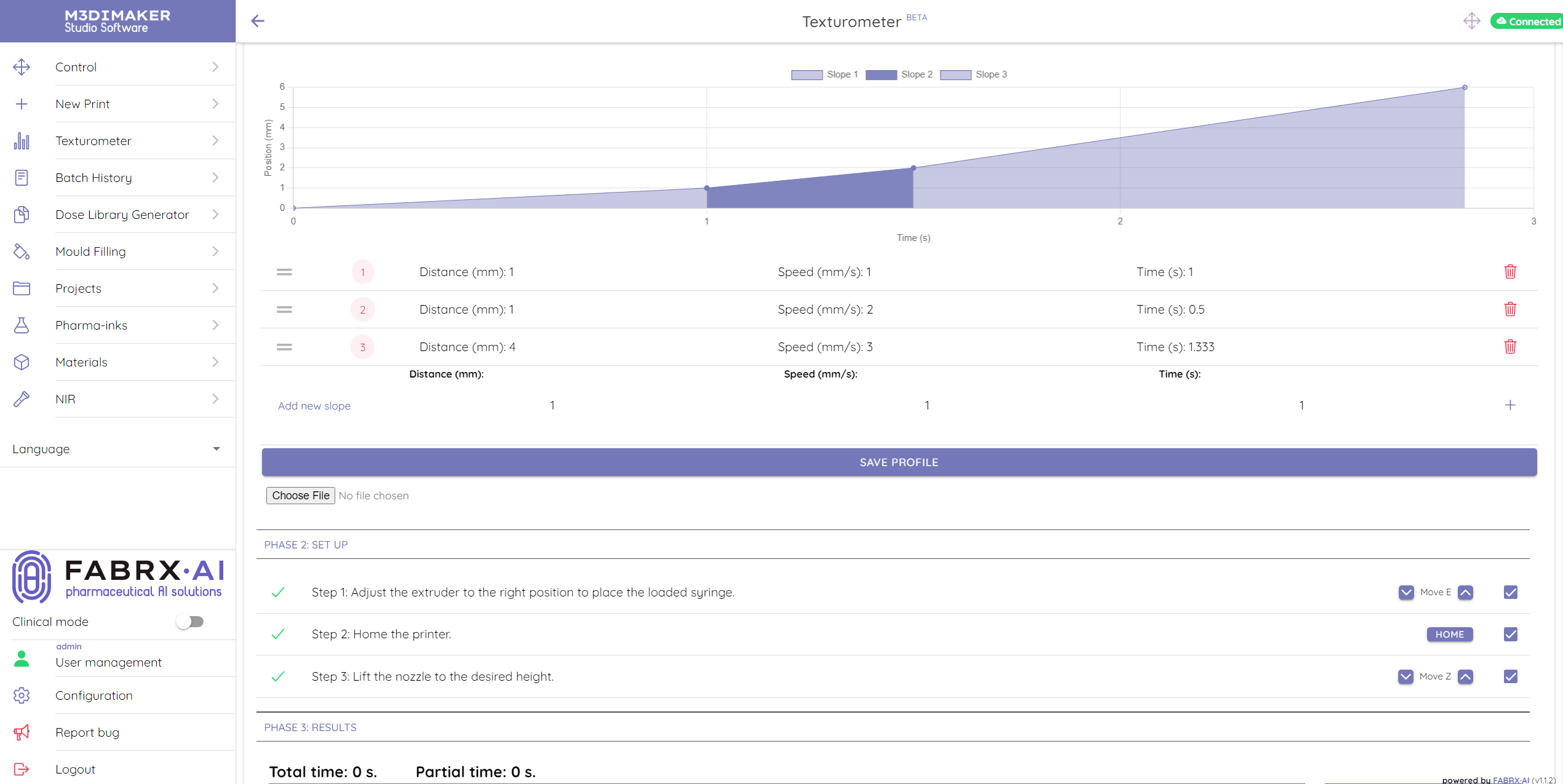

Control our in-built quality control technology using M3DIMAKER Studio. Track pressure and bubble formation using our SSE Laguna printhead, weigh and scan each tablet with our in-built balance and near-infrared spectrometer respectively.

Make protocols easy to use in busy pharmacy settings with our dose-library generator, streamlining printing into just a few clicks.

Create different groups to manage your users and printers. You can also assign different roles to each user.

Use M3DIMAKER Studio to fully control the M3DIMAKER pharmaceutical 3D printers, from choosing your 3D model to changing the 3D printing parameters. This can be freely used for research and development, or restricted for controlled use in healthcare.

Create your own pharma-inks, using our database material or adding your own. Add the preparation protocol and test and track different parameters easily.

Control our in-built quality control technology using M3DIMAKER Studio. Track pressure and bubble formation using our SSE Laguna printhead, weigh and scan each tablet with our in-built balance and near-infrared spectrometer respectively.

STUDIO

Simplifying and streamlining printer control

- Printer control

- Pharma-ink management

- Vast excipient database access

- Automated quality control

- Detailed traceabilty of all actions performed

HUB & SPOKE

Ensuring regulatory compliance

- Everything included in Studio, plus...

- Secure VPN access to database

- Secure private and public protocol sharing between different sites

- Downloadable libraries

- Performance reports

- Secure data saving and remote access for convenient auditing

M3DISEEN

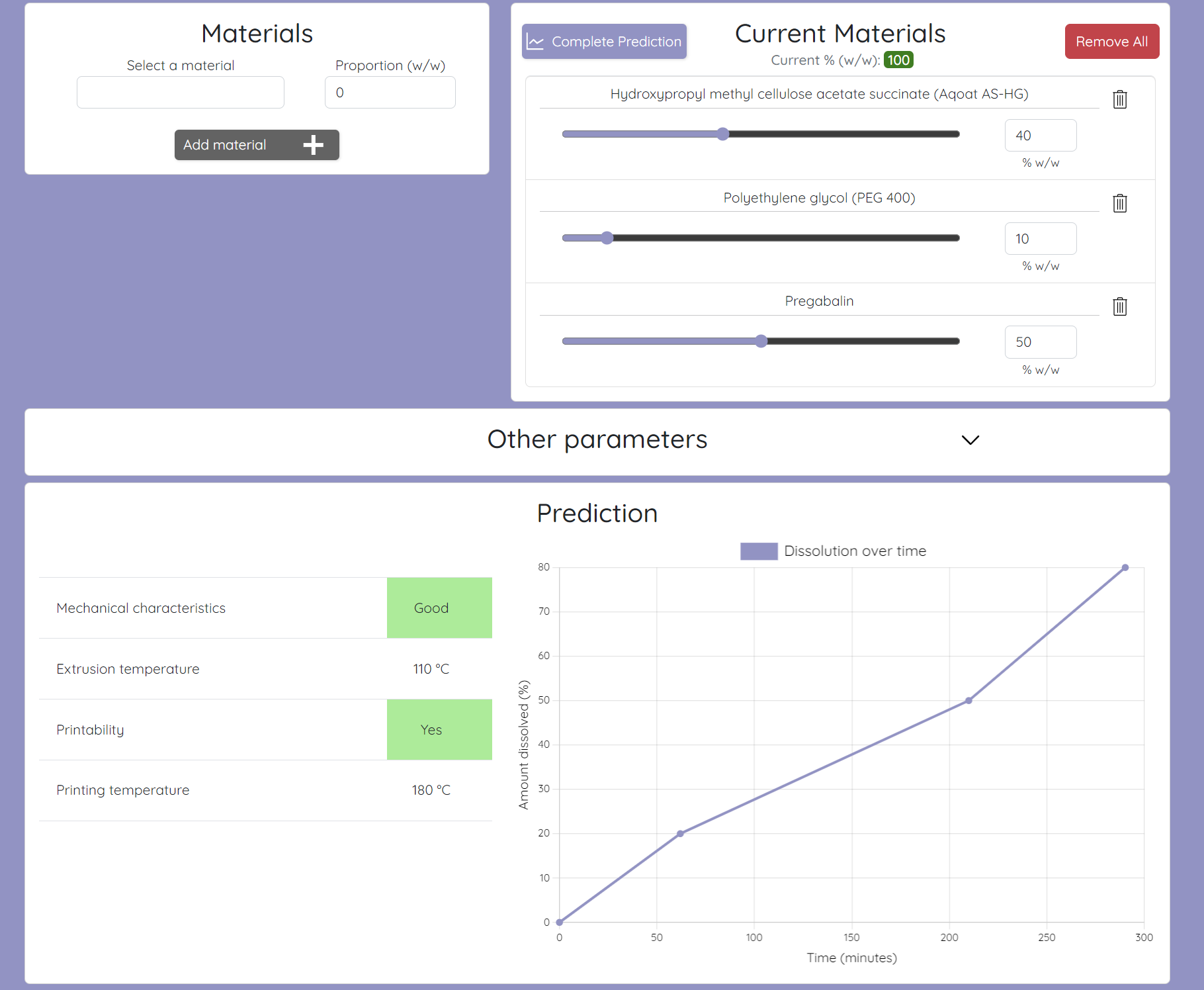

M3DISEEN is our AI-driven predicting tool designed for assessing 3D printability. By inputting your choice of drug, excipients and proportions, M3DISEEN not only predicts formulation printability but also provides recommended 3D printing parameters and dissolution insights.

Currently accessible online for free, this academic project focusses on Fused Deposition Modelling (FDM), with plans to incorporate additional 3D printing technologies in the future.